In the beginning of September 2022, a milestone was reached in the construction of wind farm Hollandse Kust Zuid with all 140 monopiles piled into the Dutch North Seabed. These monopiles are the foundation on top of which the turbines are installed.

In 2021 the start of the foundation installation for the wind farm was the first major construction activity on the Hollandse Kust Zuid offshore site. These foundations were shipped from foundation manufacturer Sif’s yard on the Maasvlakte by the installation vessel Seaway Strashnov. With the ships crane, the monopiles were lifted vertically and lowered until they touched the seabed at a depth of 17-28 metres, on top of the already installed scour protection layer. Because of its weight, the foundation penetrated the scour protection and underlying seabed. Each pile was driven to the final penetration depth by means of a hydraulic impact hammer.

The first campaign

During the first campaign, that started in July 2021 and lasted until November of that year, 34 of 140 monopiles were installed. Subsequently, a planned winter break was scheduled to look at all the lessons learnt and improve the construction process before the start of the second phase of installation in the spring of this year. During this second campaign, the remaining 106 foundations were installed.

Testament to the team

Mary Carol Anderson of Vattenfall was responsible for the foundation installation. “The ’21 campaign was quite an experience. Starting with offshore works almost a year ahead of the other construction activities not only meant we had less time to prepare, but also that all eyes were on us for the first several months. Going from installing 34 foundations in 2021 to installing 106 over 4.5 months in 2022 is a huge testament to the team!”

Bubble curtains

One of the key elements we closely monitor when piling into the seabed is related to the protection of underwater marine life. The North Sea is the home of several protected species such as harbour porpoises. These animals use sound for communication and finding their prey and can be disturbed by underwater noise from construction activities. HKZ permit manager Audrey van Mastrigt explains. “During construction of the foundations, the underwater noise that resulted from piling had to stay below a certain threshold to make sure that the effect of construction on marine life was as low as reasonably practicable. These noise thresholds differ per season and per wind farm site.”

“To reduce the noise levels, our contactor Seaway Heavy Lift used a Double Big Bubble Curtain (DBBC). This consists of two separate rings of perforated hoses, blowing air from the seabed to the water surface, producing ‘shields’ of air bubbles around the monopile. This reduces the underwater noise from the piling (read more). We were very glad that with these bubble curtains, we consistently kept the actual underwater noise during both campaigns below the thresholds.”

“In fact, using the double shields of bubbles resulted in noise levels well below the threshold, and were more effective than we initially thought. We concluded that a single bubble curtain would have been sufficient to stay within the allowed noise levels during the summer season. Nevertheless, Vattenfall continued working with the double bubble curtain.” Audrey states, “I’m proud that we got approval to maintain a double bubble curtain as we aim to reduce the noise levels as much as possible and limit the impact of the project on the marine environment. This brings extra costs and effort to the project but helps us to limit impact on marine ecology where we can.”

Apelafico

The actual impact of piling noise on fish is less well known. The scientific research project Apelafico, funded by the Dutch organisation for scientific research NWO, reached out to Vattenfall. They were interested in conducting research during piling with the aim of the research to collect information on the response of pelagic fish to piling noise, as well as testing a deterrent device specially developed to deter fish before piling. Although the foundation installation was already in full swing, Vattenfall joined the Apelafico project.

Four monitoring frames were placed in the HKZ area during the second installation campaign. These frames measured noise levels and fish activity at different distances from where piling activities took place. The fish deterrent device was used at several piling locations, giving specific information about the response of fish. Audrey added, “It was energizing to see the team’s motivation and cooperation to make this possible and to contribute to this important research. We can’t wait to see the results next year when the data is analyzed.”

Now that all the foundations are in the seabed, the rest of the HKZ construction process will continue. The next steps are to continue laying the cables, installing the turbines, and connecting them to the grid. The aim is to have all turbines installed by mid 2023. During the upcoming months Hollandse Kust Zuid Wind Farm will start to steadily deliver more and more sustainable energy to the grid as ever more turbines are being set up and connected. The Hollandse Kust Zuid project is being built by Vattenfall and owned by Vattenfall, BASF and Allianz.

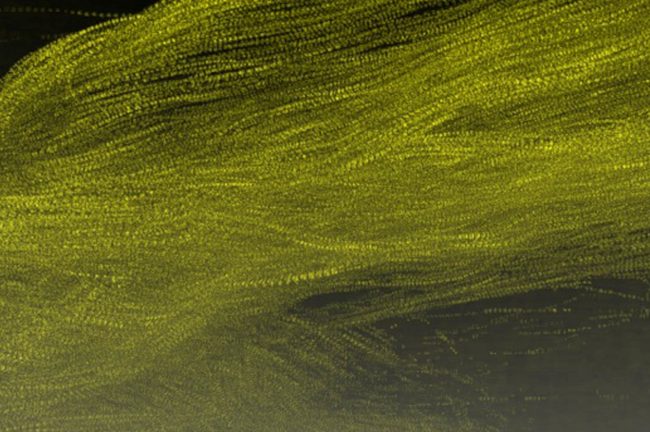

Photo: Sif Group