In just over two years’ time, all of the 140 wind turbines of the Hollandse Kust Zuid wind farm will be supplying green energy. To get there, there is a lot of work to be done. In 2021 Vattenfall will start with the first construction activities at sea. We spoke with Sven Mey, Construction Manager, about the planning and the challenges involved in working at sea. To deliver the wind farm on time, we need more than a good schedule and workable weather conditions.

June onwards: install scour protection

This summer the first activities on the Hollandse Kust Zuid wind farm will be visible on the horizon. From June onwards, the first ships will sail out to deliver rocks for the so-called scour protection to the wind turbine locations. Rocks will be placed to protect the monopiles against waves and currents, that can cause erosion of the soil around fixed structures in the seabed. This phenomenon is called scour, therefore scour protection.

July onwards: pile driving first monopiles

From July onwards the first foundations will be installed. Sven explains how this works: “Our foundation installation vessel the ‘Seaway Strashnov’ – a 183 m long and 47 m wide heavy lift vessel – will load three complete sets of monopiles and secondary steel components from the quay side of our foundation manufacturer, situated on the Maasvlakte in Rotterdam. The vessel will sail to the offshore site to install the monopiles and secondary steel parts, such as the internal airtight platform, external work platform and the boat landing.”

The monopiles vary slightly in size and weight depending on the locations where they will be installed. The heaviest and largest monopile weights 955 tons and is 75 meters long while the lightest and shortest monopile weights 735 tons and is 62 meters long. “Once the vessel arrives at the offshore site, it is positioned to the exact location. The crane of the vessel then lifts and upends the monopile into the water and lowers it until it reaches the seabed. Once the monopile is positioned correctly on the seabed, a hydraulic impact hammer is used to drive the pile into the soil to target depth.”

The challenge of this operation is not so much in the weather. “We have no influence on that,” Sven explains. “What we can influence is our level of preparedness and focus at the task at hand. And that is certainly necessary throughout the campaign, where we perform the same job 140 times. We have to keep working safely.” The team assumes that they still have to deal with corona measures. “The measures are constantly reviewed and aligned with our contractors. Moreover they are adapted to working at onshore locations as well as working at sea where we usually work in day and night shifts of twelve hours and change the teams out every 14 days.” says Sven.

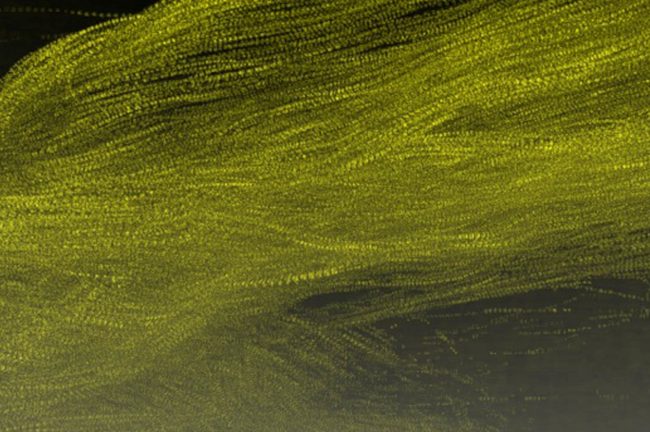

The monopile installation will continue, with a winter break, into the summer of 2022. During the construction of the Hollandse Kust Zuid wind farm, Vattenfall takes measures to protect marine mammals, that can be vulnerable to piling noise. “Before we start pile driving, we use an acoustic deterrent device to encourage marine mammals to leave the construction area. We then start piling softly, and slowly ramp up, so marine mammals have sufficient opportunity to distance themselves in case they are still in the area. During piling, we place an insulation around the piling site in the form of a double big bubble curtain that reduces the subsea piling sound. By taking these precautions, marine mammals will remain at a safe distance during the activities and we limit the water borne sound coming from the area,” Sven says.

March 2022 to April 2023: grid connection and cable installation

To transport green electricity from sea to shore, an offshore grid is needed. “This grid consists of cables and offshore transformer platforms that are required to transport the electricity efficient from the wind turbines to the substation on land,” says Sven. For Hollandse Kust Zuid, this network consists of two offshore transformer platforms, each with a base capacity of 700 megawatts, and two 220 kV export cables per platform (30-40 km long). Grid operator TenneT will develop the offshore platforms and the connection to their onshore site at Maasvlakte. The cables connecting Vattenfall’s turbines to the TenneT platforms will be installed in 2022 and 2023. “Unfortunately, we are not the first people to lay cables in the North Sea”, says Sven. “For example, there are already many telephone and data cables in the area. We map these out carefully and ensure that we have appropriate distance and protective layers between the cables when they are crossing each other.” In total, we lay about 325 kilometers of cables in the seabed.

April 2022 – April 2023 Installation wind turbines

In the spring of 2022, we will start installing wind turbines at sea. “What you may have noticed is that different activities take place side by side. This allows us to realize the project faster.” That is challenging, Sven says. “You can also choose to do foundation installation, the installation of the cables and the turbines at different times. But then overall construction takes a lot longer. Working in parallel, it is key for the team to function smoothly. That means good communication, good collaboration with suppliers and a strong focus.”

A large installation vessel of 160 meters, the Wind Osprey, will install the wind turbines. The operation starts on the Maasvlakte, where the tower parts, the nacelle and the three blades are prepared and loaded onto the vessel and transported to the offshore site. In addition to weather conditions, which cannot be planned, the number of wind turbines also presents challenges. “If we discover that we have forgotten something after we have installed the 100th turbine, we have to revisited all 140 locations. We have good procedures, so we hope to avoid moments like this. But we have to be prepared for it.”

2023: full commissioning

The first turbines of the Hollandse Kust Zuid wind farm are expected to start generating electricity in 2022. By mid-2023 all 140 wind turbines are planned to be operational, and the wind farm will be fully commissioned. The Hollandse Kust Zuid wind farm will then have a capacity of 1,500 MW.

Did you know …

- Work at sea continues 24 hours a day, 7 days a week?

- The installation of a monopile takes about 12 to 24 hours?

- Vattenfall uses weather forecasts for planning of almost all offshore operations?